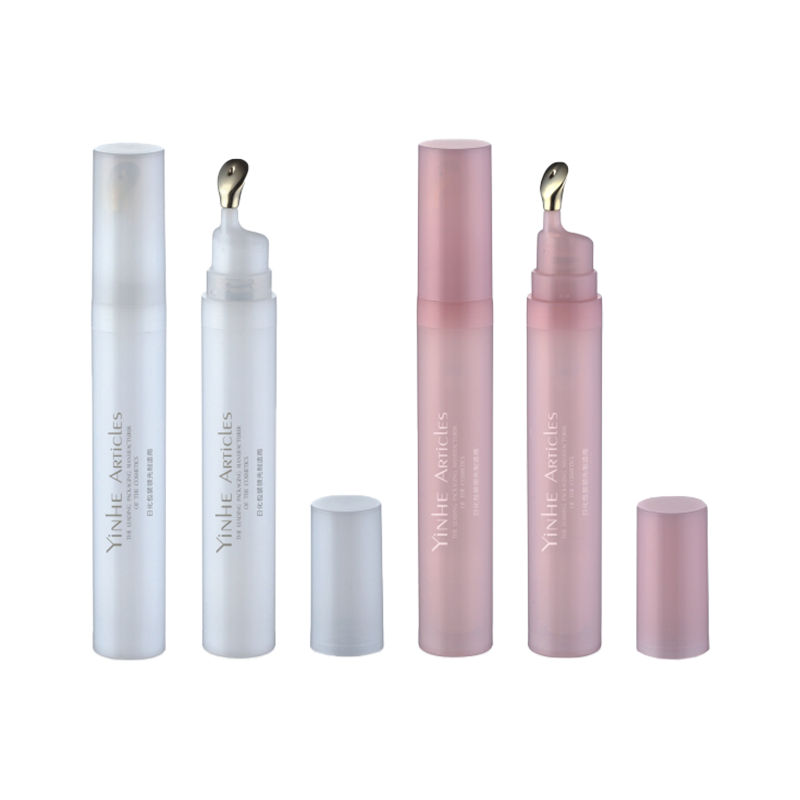

YINHE Articles - The Leading Packaging Manufacturer of The Cosmetics

Home / News / Industry News / Recycled plastic technology for cosmetic containers

The construction technology of recycled plastics for cosmetic containers(/) has made great breakthroughs in recent years. The recycling of plastic bottles dominates the technology of recycled plastic bottles, which has greatly increased the acceptance rate of plastic bottles. Plastic bottles have also repented due to low acceptance and large quantities. The image that was burnt down and contaminated the image of the scene, on the contrary, was favored by many businesses due to the repeated dominance of the capital. In order to make fun of the low-carbon global trend, many large beverage, food plastic bottles and cosmetic container manufacturers have initially given priority to purchasing and producing cosmetic containers made of recycled plastic.

According to survey data, plastics have won the competitive position of cosmetic packaging materials with reasonable prices and lighter quality. Cosmetics plastic packaging has occupied more than 72% of the market share and has become the main packaging material. Glass gives people a noble appearance. Because of its inherent characteristics, it has a place, such as bright and transparent, good chemical stability, airtight, easy to shape, and can be made into a variety of colors with metal ion colorants. Glass is currently mainly used in Among high-end cosmetic packaging and perfume packaging, the market share of cosmetic packaging is close to 20%. The market share of metal packaging is gradually declining, with a market share close to 5%.

The characteristics of high strength, light weight and resistance to breakage of plastic make it invincible in the competition. Not only that, a wide range of plastic packaging designs can be realized and implemented in a short period of time. On the other hand, the competition in the cosmetics market is very fierce today, and the packaging design is often decided in one second after the product is about to be promoted in the market, thus ensuring that the product always keeps up with market trends and consumers Demand for taste. The main applications of PET bottles and cans are concentrated in skin care products, shower gels and cosmetics.

The heat resistance of the OET raw materials of cosmetic containers needs to be improved. First of all, the heat resistance of PET cosmetic bottles needs to be advanced. PET cosmetic bottles may be exposed to low temperature when packaging beverage bottles, edible oil and many other products. Therefore, it is very important that PET bottles have sufficient heat resistance. The heat resistance of forward PET cosmetic bottles will greatly enhance the dyeing performance to enhance competitiveness. Secondly, the immutability of PET bottles. If PET cosmetic bottles can maintain the reliability and invariance of the material after repeated dominance for a long time, it will make it more useful in the waste bottle dominance market, and it will be more popular. The support of the relevant part and the individual.